Post date: 2008-05-15

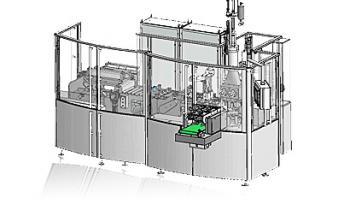

REACHING THE HIGHEST OUTPUT WORLDWiDE: THE MULTIPACK 8000 FILLING AND WRAPPING MACHINE

With an output of up to 250 packets per minute in twin execution and a filling weight and size

range of 100 to 500 g, the new developed double cell machine Multipack 8000 achieves the highest output, worldwide, for filling and wrapping pasty type products. The size flexibility within the mentioned dosing range is unique for a high speed machine, offering our customers future possibilities to produce – within the range of 100 to 500 g – packets with different footprints.

The Multipack 8000 is outstanding for its modern, attractive machine design and the intelligent control technology. In common with all the other OYSTAR Benhil filling and wrapping machines, the Multipack 8000 is characterized by exceptional filling accuracy, extremely high reliability, and a sound machine construction.

Multipack 8000 – all advantages at a glance

• The output of up to 250 packets per minuteis combined with a dosing range of 100 to 500g

• The machine is completely flexible in terms of packet sizes, both for packet height variation, and for different footprints

• The height adjustment needs only 5 minutes and can be effected without replacing parts. As an option, an electrical packet height adjustment is available

• A complete changeover of size parts (footprint and packet height) needs less than 45 minutes

• The CIP cleanable dosing system and the clear separation of kinetics and product zone allow the machine to cope with highest hygienic requirements

• The main drive is controlled by servo motor. The paper feeding system as well as the dosing which regularly have to be adjusted to varying wrapping material qualities and product consistencies, are equipped with individual servo-drives

• The future-orientated drive and control concept enables constant time dosing, highest filling accuracy, higher flexibility when using different packaging material qualities and the option to save a variety of recipes

• The dosing system completely avoids product leakage and treats the product most gently through optimum product flow

• Lifting cells combined with the newly developed dosing device guarantee perfect adjustment to different product consistencies with optimum filling level

• The modern machine concept has a clear structure providing easy acces to all machine parts for service and maintenance

• The Multipack 8000 requires less space than the former type Multipack 8362